Interview with Jennifer Brooks, Star Tribune. Not pictured are Dan Nguyen, Jasmine Nguyen, Ilsa Shobe and Jack Kotzenmacher.

Emergency BME Design and Production of 50,000 Isolation Gowns in Just Two Weeks during COVID-19!

Led by Prof. Saliterman, seventeen biomedical engineering students partnered with M Health Fairview Health System to address an immediate dire shortage of healthcare provider gowns. Faced with escalating cases of COVID-19 the partnership undertook design of a gown that could be mass produced quickly. Chronology:

Day 1, Friday, April 17, 2020

Requiring up to 15,000 gowns daily, the daunting task was addressed in Zoom meetings at noon and 7:00 pm. today. After a review of the problem and need, and consideration of various options, the team concluded that gowns could be manufactured from a simple design. Finalization of the design will be undertaken in the next 24 hours. Consideration is being given for safety, functionality, low cost, and ability for rapid manufacturing. 3M representatives kindly met with us and provided design suggestions.

Day 2, Saturday, April 18, 2020

The team organized into working groups: Design, Materials, FDA, and Manufacturing. In addition, attempts to secure gowns from sellers locally and abroad was undertaken.

Day 3, Sunday, April 19, 2020

The College of Design joined our design efforts. Efforts to locate converters (textile manufacturers) who could produce the necessary 5-10,000 gown a day necessary for a 6-8 week period was undertaken.

Day 4, Monday, April 20, 2020

Design efforts continued and meetings with M Health Minnesota were held.

Day 5, Tuesday, April 21, 2020

The design group completed preliminary drawings, prototypes and photographs to show converters for quotations.

Day 6, Wednesday, April 22, 2020

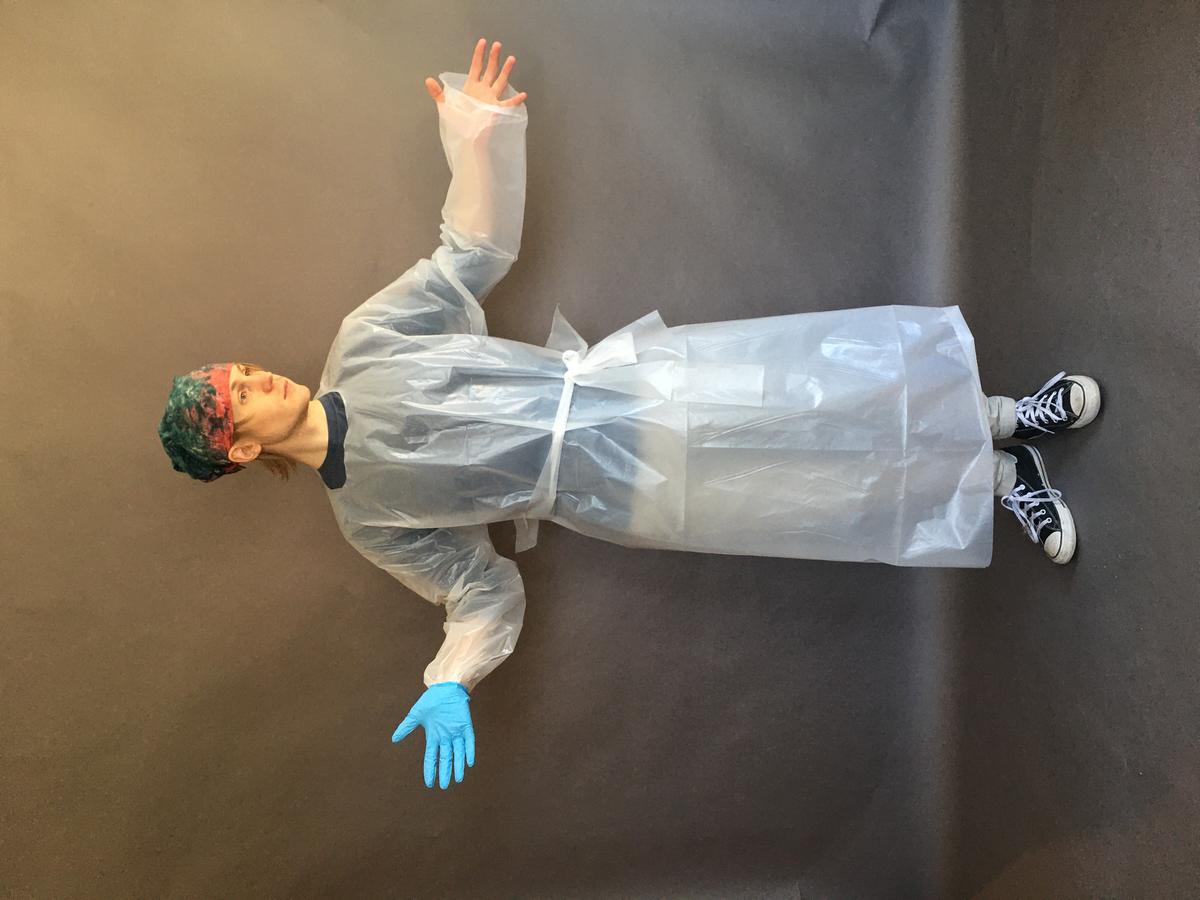

A high level meeting was held between members of the Biomedical Engineering Gown Design and Production COVID-19 team, and M. Health Fairview. Samples of our Level 1 gown design were delivered to M Health Fairview and tested, and we were asked to manufacture these immediately.

After reviewing many possible scenarios for purchasing or manufacturing gowns here and abroad, it was determined that locally sourcing material and manufacturing was by far the best way to go. This was determined after consideration of pricing, quality, material availability and reliable delivery of the nearly 5 -10 thousand gowns needed daily. There will be some ramp-up time to meet the need, but his all seems doable.

Day 7, Thursday, April 23, 2020

Material manufacturers and converters were identified and negotiations begun.

Day 8, Friday, April 24, 2020

Prof. Saliterman personally visited with the Presidents of three companies today and toured their facilities. Sample material was produced and distributed to the converters. We reviewed our design requirements, material specification, and their capabilities.

It is anticipated that Level 1 blue-tinted polyethylene gowns made of FDA certified material will be delivered by the end of the week. These were designed with input from nursing and physicians, subject to the restraints of rapid design, material selection, and manufacturing; and cost per unit. We are continuing design refinement up to the last minute.

M Health Fairview will create purchase orders with the companies it feels best suited to fulfill its requirements.

Day 9 & 10, Saturday & Sunday, April 25-26, 2020

Continuation of design modifications and pre-contract discussion.

Day 11, Monday, April 27, 2020

Drawings were updated to reflect design input, and distributed to Polar Plastics and three converters for quotation. A progress report was made to M. Health Fairview representatives in a phone call last evening. The current request is for 10,000 gowns a day, starting ASAP, for a total of 350,000 gowns over the next 4-8 weeks. We are expecting quotations and samples shortly, quality review by M Health Fairview upon receipt of the samples, and purchase orders to follow.

Day 12, Tuesday, April 28, 2020

Red Fox Innovations assembled sample units from our drawings, and has provided M Health Fairview with an estimate for production of gowns. Additional converters are being approached because of the volume needed. The sample gowns will be inspected tonight by M Health Fairview for suitability.

Day 13, Wednesday, April 29, 2020

After a final review by representatives of M Health Fairview, Red Fox innovations and Polar Plastics were selected to manufacture material and complete the first run of 10,000 gowns with anticipation of recurring orders. Complete specifications with costs were forwarded to M Health Fairview purchasing at 2:07 p.m.

Day 14, Thursday, April 30, 2020

Material was manufactured overnight and delivered to Red Fox Innovations. Sam Newell and Prof. Saliterman visited the plant and received samples of the finished gown. Red Fox Innovations was still waiting for a purchase order, but proceeded in good faith with setting up their production line and securing more bonding equipment. They have the ability to increase production of gowns with their partners, and this was communicated to M Health Fairview earlier in the week.

Day 15, Friday, May 1, 2020

Red Fox Innovations finally received a purchase order, and began production in earnest. The Gown for U team has now completed its task of designing and starting production of gowns to avert disruption of patient care, and potential closure of the hospital system. I have presented M Health Fairview with the names of other converters who can produce the quantity of gowns necessary, and their quotations. It is now in M Health Fairview’s hands to complete the necessary due-diligence and negotiations. Job well done everyone! Prof. Steven Saliterman

Sam Newell and Jon Boor Boor

Steve Anderson, Will Telken and Eric Ave'Lallemant